Core Product Advantages - Lightweight, High-Strength, Building the Future

Lightweight, High-Strength Steel Backing: Reshaping the Standard for Building Formwork

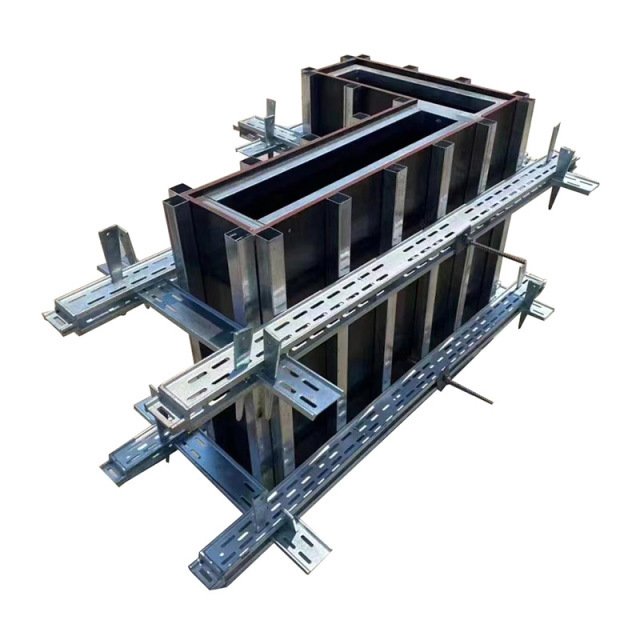

In the modern construction industry, which strives for optimal efficiency and cost, the drawbacks of traditional formwork materials (such as timber and bulky steel bracing) are becoming increasingly prominent: heavy weight makes handling difficult and labor costs high; limited turnover times lead to high long-term costs; and uneven strength affects concrete forming quality. As a professional steel backing manufacturer, our new generation of lightweight, high-strength steel backing is becoming an ideal solution for construction projects worldwide.

Why Choose Our Steel Backing? Core Advantages at a Glance:

Excellent Lightweight, Labor-Saving, and More Efficient:

Using high-quality, high-strength steel (such as Q345B) and an optimized hollow rectangular tube/special steel section design, it is up to 30%-50% lighter than traditional solid steel bracing.

This significantly reduces the labor intensity of workers during handling, installation, and disassembly, increasing work speed, shortening construction time, and effectively saving labor costs. One person can easily operate it, significantly improving construction efficiency.

Extraordinary Strength and Rigidity, the Cornerstone of Quality:

Selected steel with high yield strength and tensile strength, combined with scientific cross-sectional design, endows the steel backing with exceptional resistance to bending and deformation.

This ensures a stable and reliable formwork system, effectively resisting the tremendous lateral pressure during concrete pouring. The resulting concrete structure boasts a smooth, clean surface, sharp corners, and precise dimensions, meeting high-quality plastering standards and reducing subsequent repair costs.

Extremely Long Life, Optimal Cost:

The surface undergoes a rigorous hot-dip galvanizing treatment (zinc layer thickness ≥ 80μm) for excellent corrosion and wear resistance.

Under normal construction conditions, it can be used over 300 times, far exceeding wood and ordinary steel, significantly reducing the cost per use and providing a high return on investment.

Standardized Design, Flexible and Versatile:

A variety of standard specifications (such as 60mm x 40mm, 80mm x 40mm, 100mm x 50mm, etc.) are available, with custom lengths possible, and a modular design. Connections are quick and easy (typically using specialized fasteners, wedge pins, or bolts), allowing for easy assembly and splicing, perfectly adapting to the formwork reinforcement needs of various structures of varying sizes and shapes, such as shear walls, columns, beams, and floor slabs.

Stable, safe, and environmentally friendly:

The stable structure and secure connections provide a more reliable and secure environment for construction at height and in complex environments.

The high reuse rate significantly reduces wood consumption and construction waste, and the steel itself is 100% recyclable, aligning with global green building and sustainable development concepts.

Wide Applications: Whether it's residential buildings, commercial complexes, industrial plants, or large-scale infrastructure projects requiring extreme precision, such as bridges and nuclear power plants, our steel backing is a wise choice for improving project quality, efficiency, and cost-effectiveness.

Start now and experience efficient construction!

Contact us for samples and professional selection advice